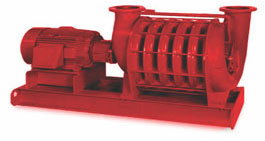

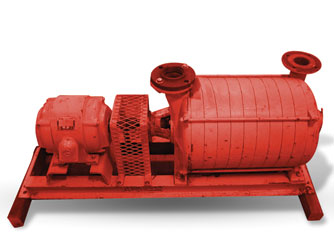

Multistage centrifugal Blower consists of a rotating shaft and multi-impellers operating in specially designed Inlet Housing. Outlet Housing and Intermediate Sections. The impellers are accurately balanced. This is a multi-impeller and multi-stage assembly. The number of stages and speed are selected to suit the customer’s exact requirements.

Drives:

They are usually V-Belt driven from electric motors.In the larger sizes the machines can be direct coupled to electric motors.

Mountings:

The mahine and motor can be mounted on base frame fabricated and machined from steel in plain Horizotal in line style or a box type vertical style saving the space.

|

|

Advantages:

|

No Fine internal clearance or wearing parts requiring lubrication except Bearing. |

|

Air delivered is free from oil,vapour,moisture or other contamination. |

|

Air is completely uniform and free from pulsation. |

|

Power consumption varies with the volume of Air delivered. |

|

Dynamically Balanced impellers minimise vibrations. |

|

Space Efficient design. |

|

Versatile: Can be used as Blower for pressure and as Exhausters for suction. |

Application:

|

Vacuum Cleaning. |

|

Pneumatic Conveying. |

|

Steam and condensate extraction. |

|

Gas Blowing and Boosting. |

|

Aeration of Powders. |

|

Furnace Blowing. |

|

Agitation of liquids. |

|

Cooling and Drying. |

|

Textile machinery. |

|

Machine Tools. |

|

|

Range:

|

Air Flow : 80 To 400 cfm |

|

Vacuum : 650 to 2500 mm wc |

|

Pressure : 650 to 4000 mm wc. |

|

Spares:

|

Silencer |

|

Filter |

|

Anti – Vibration Pads |

|

|